Support various colors and shape customization for cover glass.

Thickness of cover glass: 0.55, 0.7, 1.1, 2.0, 3.0, 4.0, 5.0, 6.0 to maxim 12 mm.

Color: gradient color logo customization, never fall off ceramic ink printing, UV ink printing

Shape customization: 3D cover glass customization, drilling, grooving, sliders, polishing treatment, etc

Special treatment of cover glass

Basic concepts:

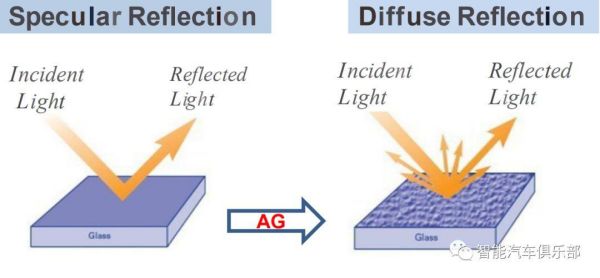

AG: anti-glare glass, also known as non-reflective glass, the effect of multi-angle diffuse reflection is achieved after the special treatment of one or two sides on the glass surfacet, so as to improve the visual angle of the picture, reduce the interference of ambient light, reduce screen reflection.

Product performance

Gloss

First of all, we know that glossiness is one of the most important parameters for us to control AG glass. For glossiness, we hope that the glossiness of this piece of glass should be relatively uniform.For example, like on this piece of 15-inch cover glass, we want to measure 5 points, or even more points, its gloss to be controlled within 10, so we think it is a relatively good gloss control.

Haze

Haze in AG glass industry, It is regulated as a reference value, but even a reference, if you can make it the same haze of each batch production, we think the production capacity is up to standard. For some bad AG cover glass, we found that each batch produced, its haze has a large deviation, this will lead to a big difference when cover glass used.

But in addition to glossiness and haze, what other indicators will also affect the quality of AG glass?

Roughness

For a good AG cover glass, its surface roughness is very uniform. For example, Vantouch cover glass can achieve below 0.06 surface roughness. If the granularity is relatively coarse, it will directly affect the display effect of AG glass.

transmittance

As for the transmittance index, other AG glass factories may not deliberately control this index. As for us, We think that the glass after etching AG treatment should at least not affect the transmittance of the glass itself.

Basic concepts:

Antireflection glass (AR) is also called anti-reflection glass. AR glass is a nano-optical multilayer film with a certain film structure that is plated on the glass substrate by vertical vacuum magnetron sputtering method based on optical film interference principle.

The visible light transmittance of glass increased from 89% to over 98%, and the surface reflected light decreased from 8% to less than 1%.For example, double-sided four-layer AR film system, the light transmittance can be as high as 98% and the reflectivity drops to less than 1%.

In outdoor strong light irradiation, high penetration and no reflection, anti-glare, greatly improve the contrast and clarity of flat panel display in strong light environment, and at the same time partly improve the brightness of the display, with the function of high clarity and moistening eyes.

Product performance

A. Visible light transmittance increased from 89% of ordinary glass to over 98% (up to 99.5%), making it the most transparent glass in the world;

B. The visible light reflectivity is reduced from 8% of ordinary glass to less than 1% (up to 0.2% at the lowest level), effectively reducing the defect of whitening caused by strong light behind, and enjoying clearer image quality;

C. Uv spectrum penetration rate <3%, can effectively block the uv damage to the eyes.

1. Basic Concepts:

AF anti - fouling anti - fingerprint glass is coated with a layer of nano-chemical material on the outer surface of the glass according to the lotus leaf principle, which can reduce the surface tension of the glass to the minimum, reduce the contact area between dust and the glass surface by 90%, and make it have strong water-repellent, oil-resistant and fingerprint-resistant ability,making glass panel to keep bright and clean for a long time.

Ceramic ink

Ceramic ink melts into glass after the physical intensification of instant baking and instant cooling at 680° C, realizing the very strong adhesion and durability of the color on the glass, which can withstand years of sunlight.

It has a certain resistance to atmospheric corrosion and is the first choice for the processing of outdoor display cover glass.