Optical Bonding is the process of improving module quality by filling the gap between touch screen and LCD screen.The silicone adhesive we use has the best performance till now.Compared to non-Optical Bonding , silicone has more advantages over touch control module, and can be better used for anti-yellowing.

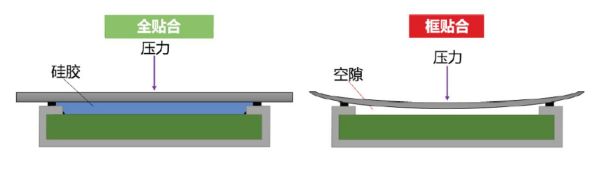

Comparison of Optical bonding and air bonding

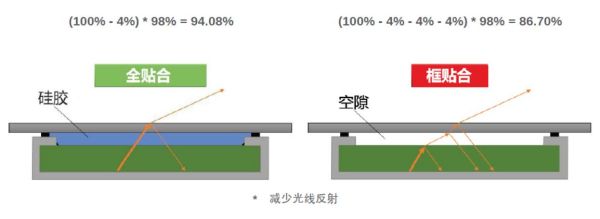

Reduce reflections and increase viewability (outdoor has largest advantage)

The main advantage of optical bonding is the improved readability and contrast of the display, even under intense lighting conditions and wide viewing angles. In air bonding, light from an external source passes through the panel and air gap (between the display and the glass), causing its refraction. This phenomenon means that some of the light is reflected back, creating reflections on the screen. When the backlight of LCD passes the air gap and touch, the same thing happens.

Increase the overall brightness of the equipment

Placing the cover glass on top of the display reduces the brightness of the product due to the backlight reflection and transmission of the glass (usually 98%).For optical bonding, this reflection does not occur, so the brightness of the display increases by about 10%.

Protection of dust and condensation

There is no gap between the LCD and the touch, so there is no space for dust particles and condensation. This will greatly help readability and image quality for the optical bonding product, which will be very helpful for outdoor utilization.

Increased physical endurance

Replacing the gap with OCA/SCA increases its physical strength. At the same time, it will also Improve heat resistance. Increased physical endurance allows an optical bonding module using in public places, factories and military applications.